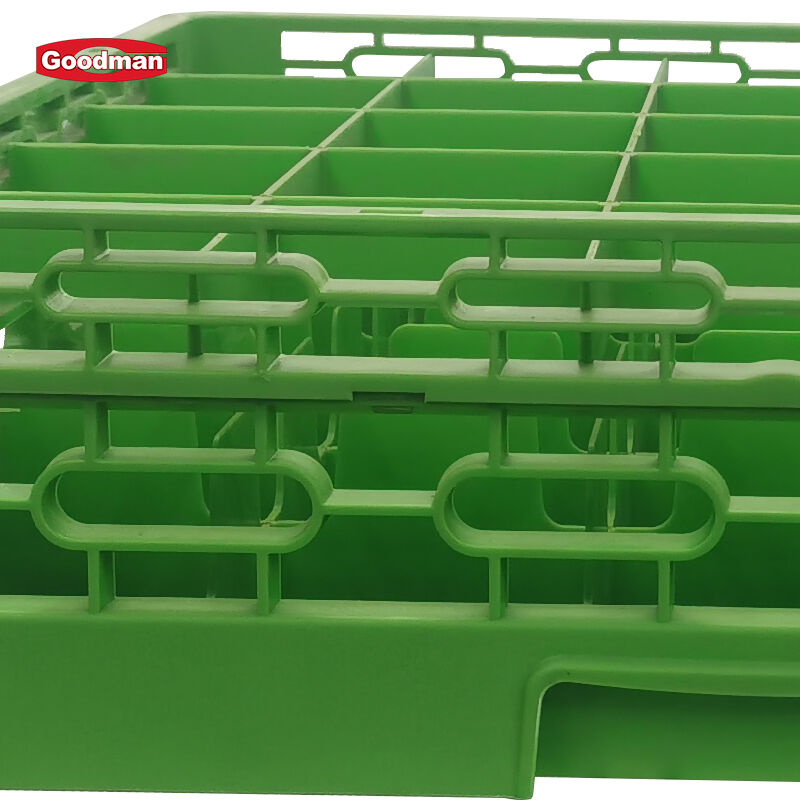

plastový skleněný regál

Plastová regál na sklenice představuje revoluční řešení pro uskladnění a organizaci sklenic, které bylo navrženo tak, aby vyhovělo náročným požadavkům restaurací, barů, jídelen a komerčních kuchyní. Tento inovativní systém uskladnění kombinuje odolnost, funkčnost a ekonomickou výhodnost, čímž zajišťuje vynikající výkon ve vysokozátěžových prostředích. Plastový regál na sklenice má modulární konstrukci vyrobenou z vysoce kvalitního polypropylenu nebo polyethylenu, který je navržen tak, aby odolal opakovaným cyklům mytí a intenzivnímu každodennímu používání. Jeho hlavní funkcí je bezpečné uchycení různých typů sklenic během procesů mytí, sušení, uskladnění a přepravy. Regál obsahuje strategicky umístěné oddíly, které umožňují uložení různých velikostí sklenic – od mini skleniček po velké hrnce – a tím zajišťují optimální využití prostoru a zabraňují jejich poškození. Mezi pokročilé technologické prvky patří zesílené rohové spoje, které zajišťují vynikající strukturální pevnost, zatímco mřížový design podporuje lepší proudění vzduchu a umožňuje rychlejší sušení. Plastový regál využívá speciální držákové vzory na spodní ploše, které zabraňují sklouznutí během manipulace a skládání. Odolnost vůči teplotám umožňuje regálu efektivně fungovat v myčkách pracujících za vysokých teplot, obvykle v rozmezí od 60 do 82 stupňů Celsia. Lehká konstrukce snižuje únavu obsluhy, a přesto zachovává vysokou nosnost. Aplikace se rozprostírají do různorodých komerčních prostředí, včetně hotelových restaurací, lodí na trase, nemocničních jídelních zařízení, školních jídelen a cateringových provozů. Plastový regál na sklenice je nepostradatelný ve vysokofrekvenčních prostředích, kde efektivní manipulace se sklenicemi přímo ovlivňuje provozní produktivitu. Jeho kompatibilita se standardními komerčními mycími systémy umožňuje bezproblémovou integraci, zatímco skládací design optimalizuje využití skladovacího prostoru, když není používán. Chemická odolnost regálu zajišťuje dlouhou životnost i při vystavení komerčním čisticím prostředkům a desinfekčním roztokům, které jsou běžně používány v profesionálních provozech stravování.