mop bucket trolley

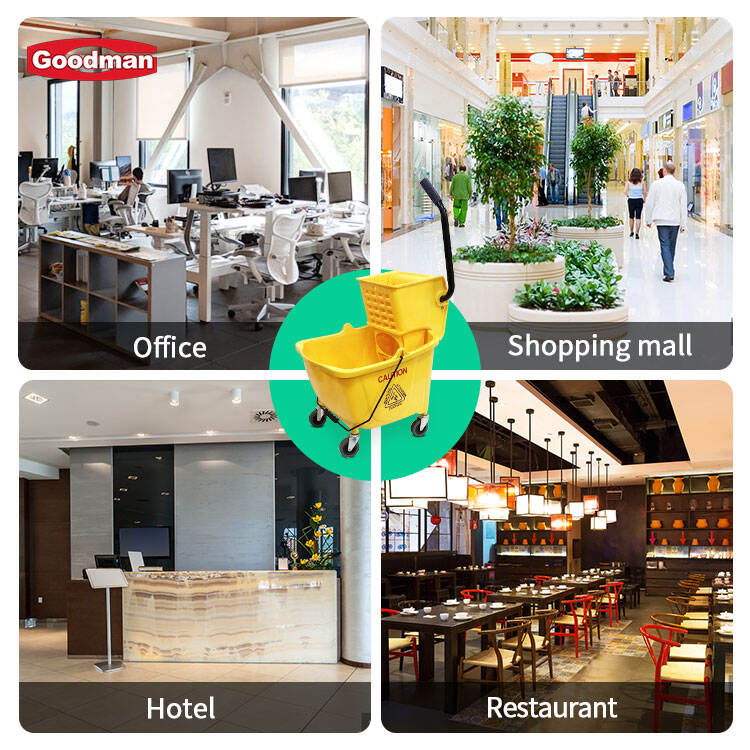

A mop bucket trolley represents an essential piece of commercial and industrial cleaning equipment designed to streamline floor maintenance operations across various facilities. This mobile cleaning system combines a high-capacity water reservoir with an integrated wringer mechanism, mounted on a sturdy wheeled platform for enhanced mobility and efficiency. The mop bucket trolley serves as the cornerstone of professional cleaning protocols, enabling custodial staff to cover extensive areas without frequent water changes or cumbersome equipment transportation. Modern mop bucket trolley units incorporate advanced engineering features that prioritize durability, functionality, and user safety. The primary structure consists of a reinforced polypropylene or steel bucket capable of holding substantial water volumes, typically ranging from 20 to 40 liters. This generous capacity ensures extended cleaning sessions without interruption for refills. The integrated wringer system utilizes either a side-press or down-press mechanism, allowing operators to extract excess water from mops efficiently while maintaining optimal moisture levels for effective floor cleaning. The wheeled base features robust casters designed to navigate various floor surfaces smoothly, including carpeted areas, tile floors, and concrete surfaces. Many mop bucket trolley models incorporate additional storage compartments for cleaning supplies, spare mops, and chemical containers, transforming the unit into a comprehensive mobile cleaning station. Technological advancements have introduced color-coding systems to prevent cross-contamination between different cleaning zones, particularly crucial in healthcare and food service environments. Some premium mop bucket trolley variants feature graduated measurement markings for precise chemical dilution, ensuring consistent cleaning results while minimizing waste. The ergonomic design principles embedded in modern mop bucket trolley construction reduce operator fatigue and minimize the risk of workplace injuries. Applications span across numerous sectors including hospitals, schools, offices, retail establishments, hotels, and manufacturing facilities, where maintaining pristine floor conditions directly impacts safety, hygiene, and professional appearance.